difference between quartz and granite

Today, I will share with you something about the difference between quartz and granite.

In the expansive world of stone materials, granite and engineered quartz stand out as two highly sought-after, premium options, commonly used for countertops yet with notable differences in many aspects.

**Usage Scenarios**

Granite is highly suitable for outdoor applications due to its natural durability. Its strength allows it to withstand various environmental elements, making it a popular choice for outdoor walls and flooring. Indoors, granite is also widely used for floors, walls, and countertops. Engineered quartz, on the other hand, is mainly suited for indoor countertops and occasionally for wall applications, as outdoor exposure may affect its longevity. Unlike granite, quartz cannot endure prolonged exposure to sunlight, rain, or other elements.

**Maintenance and Care**

Granite and engineered quartz differ in maintenance needs. Granite countertops, being porous, require periodic sealing to prevent stains and liquid absorption. Engineered quartz, with its non-porous surface, does not require sealing and is easier to clean, making it more suitable for high-maintenance environments. Maintenance costs are a crucial factor for importers, as they influence customers’ purchasing decisions.

**Material Source**

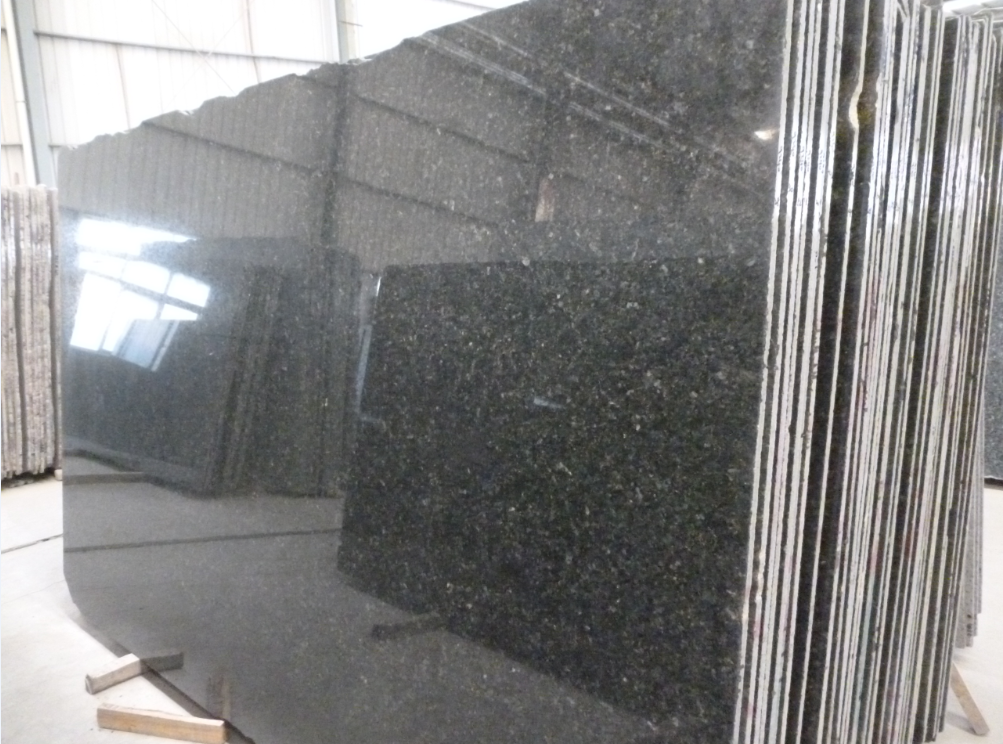

Granite is a natural stone sourced directly from quarries around the world, with each slab uniquely crafted by nature. In contrast, engineered quartz is carefully manufactured through a series of blending, compressing, and refining processes, resulting in a consistent and customizable final product crafted by advanced technology.

**Environmental Impact and Sustainability**

As environmental awareness grows, customers are increasingly focused on the sustainability of materials. Granite extraction has some environmental impact, while quartz manufacturing also requires energy and resources. However, many quartz manufacturers use eco-friendly materials and processes to reduce their carbon footprint, even achieving certifications. For importers, sustainability is a vital consideration, especially in markets with stringent environmental standards.

**Color and Design**

Because granite is naturally formed, its colors and patterns are limited to what is found in nature, making each type unique and finite. Engineered quartz, as a man-made product, allows manufacturers to design an array of colors and patterns, following trends and continuously releasing new designs to meet varying customer preferences.

**Antibacterial Properties**

Antibacterial performance is an important consideration, particularly for modern kitchens and bathrooms. Engineered quartz, being non-porous, offers superior resistance to bacteria, while granite, if left unsealed, may harbor bacteria within its pores. This difference in antibacterial properties makes quartz especially attractive for home and kitchen-focused importers.

**Branding Potential**

Many stone importers opt to establish their own engineered quartz brands, similar to how a tile factory might operate multiple tile brands. Since engineered quartz is a manufactured product, a company’s quartz brand can feature exclusive, unique designs tailored to that brand.

Granite, however, is a different story: it’s challenging for a granite brand to offer designs that no one else has. This would only be possible if you became the exclusive distributor of a particular granite quarry, but realistically, how many granite quarries can you secure exclusive rights to?

**Regional Variations**

Granite is sourced from many famous regions. Brazilian granite, known for its vibrant colors and durability, is popular worldwide. India's "Indian Black" and "Black Galaxy" varieties are highly valued for their unique color and texture, often used in large architectural projects. China's G603 and Shanxi Black granite are also widely known, with China’s extensive granite resources and high-quality options holding a strong position in global markets. Engineered quartz is primarily produced in China, where high quality meets cost-efficiency due to advanced manufacturing expertise. India is also emerging as a competitive quartz producer with lower labor costs, making it an attractive option for importers seeking budget-friendly alternatives. Quartz from other countries often comes at a higher price, lacking the cost advantage of Chinese and Indian options.

**Cost-Effectiveness**

Importers should assess the cost-effectiveness of granite and engineered quartz carefully. Brazilian granite, for example, is typically priced higher than granite from India or China. With engineered quartz, pricing varies widely depending on the factory and product positioning.

Naturally, different clients seek different qualities in their stone products. Some are willing to pay a premium for designs that suit their aesthetic, whether natural or engineered, while others prioritize low-cost options as long as quality remains acceptable.

This ultimately depends on your market positioning. Your company can maintain high-end, mid-range, and budget product lines to meet varied customer needs.

For a high-end line, consider partnering with a well-known quartz brand or importing beautiful natural granite from Brazil.

For a mid-range line, you can work with us to source attractive quartz designs from China and establish your own quartz brand.

For a budget line, branding is still possible. You may contact us to procure affordable quartz from China or India. Additionally, China offers competitively priced natural granite, which is low-cost not due to inferior quality but because of the highly competitive granite market there, which drives down market prices.

conclusion of difference between quartz and granite

After reading this article about the difference between quartz and granite, you might think, “It seems like engineered quartz is much better than granite!” But I’m not trying to favor quartz—I truly value natural granite as well. Each has unique strengths and weaknesses, and both are excellent choices.

In summary, granite and engineered quartz each offer distinct advantages, making both valuable for different market demands, budgets, and project needs. Whether it’s the natural strength and beauty of granite or the versatile appeal of quartz, both present exciting business opportunities for stone importers to profit and succeed.